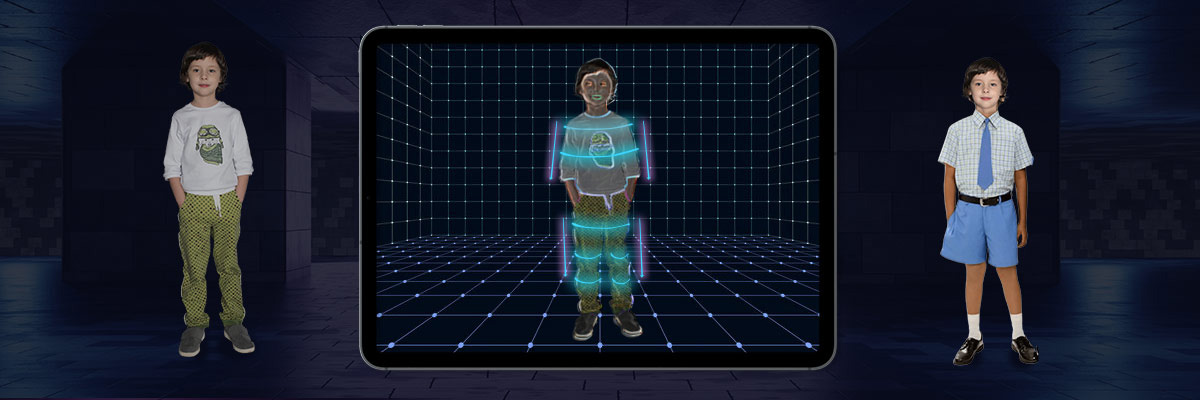

PoC for automated body-measuring tool using machine learning

The Challenge

The business of tailoring inevitably involves a phase where the measurement of each individual is collected manually – this is often time-consuming at scale and involves contact and concerns of privacy.

The problem called for a less intrusive, automated, intelligent solution that would estimate the tailorable measurements utilizing the latest technologies, thereby augmenting the efficiency and speed of delivering the clothing required to be stitched.

Realizing the wide-ranging application of a product that could automate body measurements, the client planned to roll-out an innovative solution that would initially automate and fast-track uniform-size measurements for school children, and could later be utilized in various different ways across different sectors.

Even though they had an innovative solution conceptualized, the client lacked the technical expertise to create a POC for the envisaged solution. They required an IT partner who was willing to think out-of-the-box, and approached Experion to leverage our unique capabilities in cutting-edge technologies like artificial intelligence and machine learning to conduct a flawless POC.

Our Solution

Experion proposed a three-step solution which involved:

- Scanning of the body: The full body image scan was to be done using a true depth camera, to render a watertight 3D mesh estimate of the body on a 1:1 scale.

- Identification of the key points: To generate the body measurement from the watertight mesh obtained using the camera, the points had to be identified as per the ISO-8559-1 definitions which deal with the standardization of body measurement definitions for the clothing industry. To cater to this Experion designed and developed an intelligent algorithm trained across different samples of mesh sampled from the population to identify the key point as per the definitions (Eg: Shoulder, Wait, Chest, etc.)

- Estimate Body Measurement: Once the key points are identified, the mesh coordinates that define the body parts to be measured are used for a complex set of mathematical equations whose solution would estimate the measurement required to tailoring.

The solution algorithm was mainly developed using Python 3.6 with Computer Vision, Deep Learning, and Scientific Computation Libraries. The mesh input was generated by the depth sensor camera which would form the input to the solution.

The measurements, the estimated key points, and the measurement locus were presented on a graphic interface for the customer to verify and approve or re-attempt for further fixes.

The proposed solution is a major breakthrough in automatic body size measurement – it paves the way for digitalization that improves accuracy using depth image processing. It reduces unnecessary wastage of time and effort and since it involves the usage of depth sensors, the output can be used for a variety of applications such as foot-size determination, medical diagnostics, etc.

Business Impact

- Successful POC for a breakthrough solution that could revolutionize the retail tailoring business

- Contactless body-size measurement ensures social distancing & complete body privacy

- Batch processing and automation ensures minimum human supervision with reduced measurement time facilitating more business volumes

- Secure digital storage enables re-use of measurements